Steelfibre batch →

Steelfibre grades:

Our steel fibre grades are adapted for the use in different polymers.

Thermoplastic polymers are known as electrically non-conductive without any conductive fillers.

Due to this property the use of thermoplastic polymers for housings of electric or electronic devices is limited because generelly EMI-shielding is required.

Concerning the ESD behaviour thermoplastics as non conductive materials are as well critical for use in the mentioned applications.

However thermoplastic polymers may be made electrically conductive by the use of:

Electrically conductive coating of the surface of housings

Use of thermoplastic resins filled with electrical conductive fillers or fibres

To achieve an optimal solution for the EMI-shielding housings made from plastics the use of a highly conductive, fibrous filler in form of steel fibre batch is a successful way.

Description of the steel fibre batch:

Our steel fibre batch is made from an alloy of stainless steel with a high percentage of marten-sit to increase the level of magnetic permeability.

The fibres have a diameter of eight or twelf micron and are available in form of masterbatch. The granule consists of a bundle of up to 14000 parallel oriented filaments. The filaments are coated with an appropriate binder and the granules have chop lengths of 4-6 mm according to the wishes of our customers.

Principle of efficacy:

Due to the high fineness of the filaments there is a highly equal distribution of the filaments in the melt possible which subsequently leads to a dense network of steel fibres in three di-mensions. An EMI-shielding is achieved according the principle of the cage of Faraday.

Advantages of thermoplastics filled with steelfibre batch in comparison to electrical conductive coatings and thermoplastics filled with conductive fillers:

- Only low loadings required(dependant on the requirements of about 4-10 wt% in comparison to about

- 20-50 wt% of carbon black; also the use of carbon fibres requires relatively high loadings because of

- the specific electric conductivity being lower than that of steel fibres

- no impact on mechanical properties

- more independant in colour than with use of carbon black or carbon fibres

- more efficient EMI-shielding with increasing frequency

- lower resonance effects at high frequencies

- considerable cost advantage (up to 20 times less) in comparison to the coating of the surface of housings

Downloads

Product presentation Steel fiber batch

Product presentation Steel fiber batch

Format: PDF-File

Extent: 7 Pages Processing Instructions Steel fiber batch

Processing Instructions Steel fiber batch

Format: PDF-File

Extent: 1 Page

Steelfibre grades:

Our steel fibre grades are adapted for the use in different polymers.

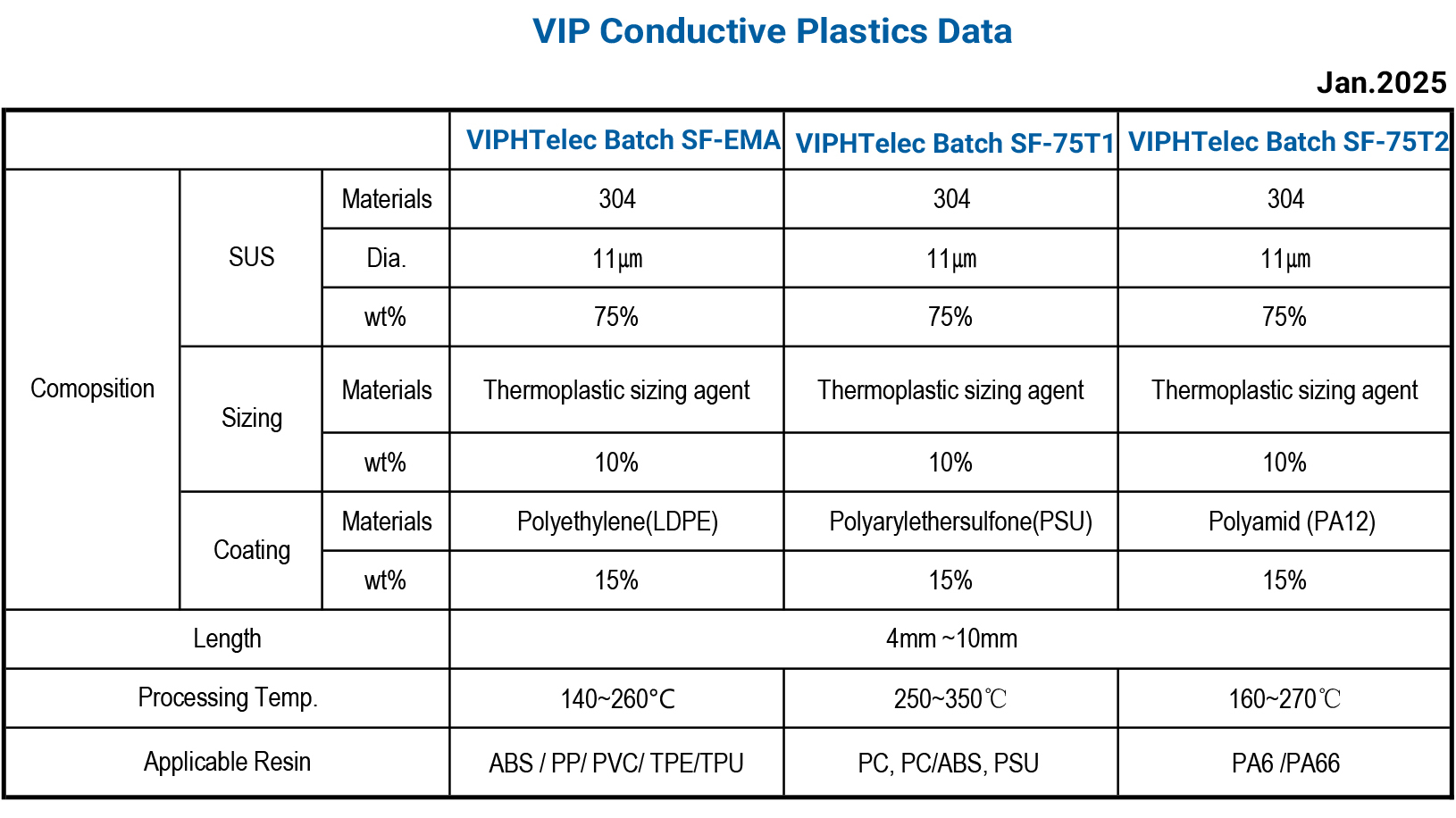

Item | Metal fibre wt | Coating | Sizing | Used for |

VIPHTelec SF75-EMA | 75 % | Thermoplastic Resin | Thermoplastic Polyester | PE, PP, PS,PVC, POM, TPE, TPU |

VIPHTelec SF75-T1 | 75 % | Thermoplastic Resin | Thermoplastic Polyester | PC, PC/ABS, PBT, PEI, PSU |

VIPHTelec SF75-T2 | 75 % | Thermoplastic Resin | Thermoplastic Polyester | PA, PET, PBT |

VIPHTelec SF75-T3 | 75 % | Thermoplastic Resin | Thermoplastic Polyester | ABS, SAN |

Thermoplastic polymers are known as electrically non-conductive without any conductive fillers.

Due to this property the use of thermoplastic polymers for housings of electric or electronic devices is limited because generelly EMI-shielding is required.

Concerning the ESD behaviour thermoplastics as non conductive materials are as well critical for use in the mentioned applications.

However thermoplastic polymers may be made electrically conductive by the use of:

Electrically conductive coating of the surface of housings

Use of thermoplastic resins filled with electrical conductive fillers or fibres

To achieve an optimal solution for the EMI-shielding housings made from plastics the use of a highly conductive, fibrous filler in form of steel fibre batch is a successful way.

Description of the steel fibre batch:

Our steel fibre batch is made from an alloy of stainless steel with a high percentage of marten-sit to increase the level of magnetic permeability.

The fibres have a diameter of eight or twelf micron and are available in form of masterbatch. The granule consists of a bundle of up to 14000 parallel oriented filaments. The filaments are coated with an appropriate binder and the granules have chop lengths of 4-6 mm according to the wishes of our customers.

Principle of efficacy:

Due to the high fineness of the filaments there is a highly equal distribution of the filaments in the melt possible which subsequently leads to a dense network of steel fibres in three di-mensions. An EMI-shielding is achieved according the principle of the cage of Faraday.

Advantages of thermoplastics filled with steelfibre batch in comparison to electrical conductive coatings and thermoplastics filled with conductive fillers:

- Only low loadings required(dependant on the requirements of about 4-10 wt% in comparison to about

- 20-50 wt% of carbon black; also the use of carbon fibres requires relatively high loadings because of

- the specific electric conductivity being lower than that of steel fibres

- no impact on mechanical properties

- more independant in colour than with use of carbon black or carbon fibres

- more efficient EMI-shielding with increasing frequency

- lower resonance effects at high frequencies

- considerable cost advantage (up to 20 times less) in comparison to the coating of the surface of housings

Downloads

Product presentation Steel fiber batch

Product presentation Steel fiber batch

Format: PDF-File

Extent: 7 Pages